As a plant operator, are you looking for a more cost-effective way of repairing boiler tubes? Then check out Thermo International’s latest piece on induction heating technology.

Many modern power plants are still relying on old methods of replacing worn-out boiler tubes—methods that are not only primitive but also damage the surrounding sheet, resulting in unnecessary expenditures.

But not all old tech is useless, as Thermo International indicates in its latest expert piece.

The leader in induction technology has released a new article that explains how you can use induction heating machines as a cost-effective way of repairing and replacing worn-out boiler tubes.

Visit https://thermointernational.com/2022/10/28/power-plant-challenge-solved-with-induction-heating-machines/ for more information.

In the article, Thermo International explains how the induction heating process differs from traditional methods of repairing boiler tubes and how you can benefit from this innovative technique.

As global economic factors continue to impact all industries, finding ways to curb bottom-line expenses becomes crucial even for those in the utilities industries. Furthermore, as ongoing maintenance costs can drastically impact a facility’s output and revenue, finding ways to reduce downtime is critical.

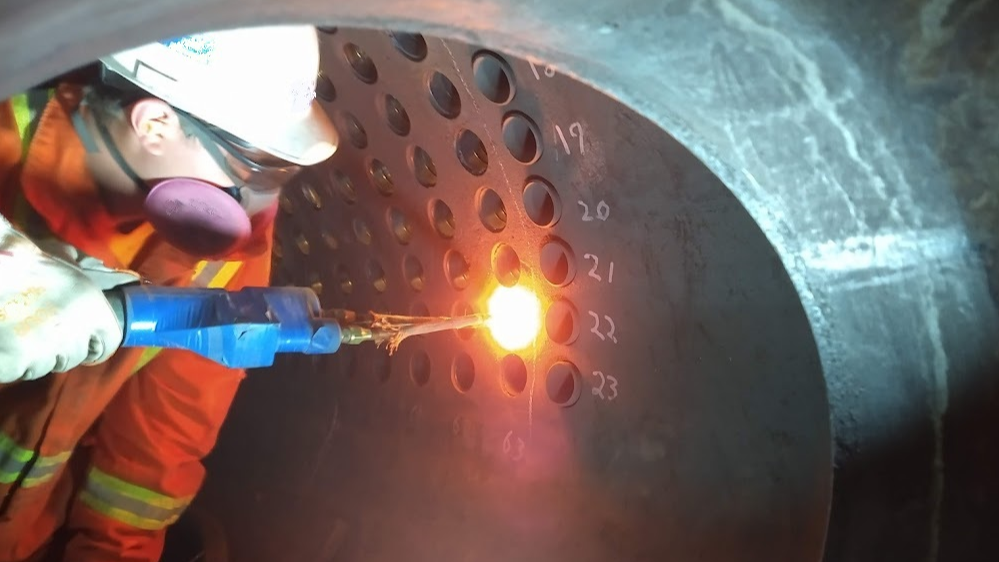

Traditional repair work on boiler pipes involves cutting around a damaged area and using a hammer and chisel to knock the section out. However, Thermo International explains that this high-impact method can often result in further damage to the surrounding pipework, which can then require additional welding and sheet rolling to repair.

To prevent this extraneous damage, Thermo International explains how their innovative induction heating method can rapidly heat and shrink a damaged section, making it malleable for easier removal. Additionally, as induction heating has a short time-to-temperature ratio, it can also be a faster process than using a hammer and chisel.

If you would like to utilize induction heating for your own pipework replacements, you can rent a range of portable units from Thermo International. Having worked with induction heating machines for several years, the company’s team can also offer you other induction-related services such as bolt heating, heat treatments, induction brazing, and tempering.

The company’s website has further details regarding induction heating, including videos of the process and articles regarding its use for various maintenance and construction needs.

A recent client of Thermo International said, “Their top-of-the-line induction heating machines have helped our company increase productivity along with their world-class technical support.”

Learn how induction heating can save your facility money on boiler repair costs with Thermo International.

For more information, you can visit https://thermointernational.com/2022/10/28/power-plant-challenge-solved-with-induction-heating-machines/ where you can access the full article.