This Ultra-Precise Tabletop Maskless Lithography System Is Ideal For Bio Labs

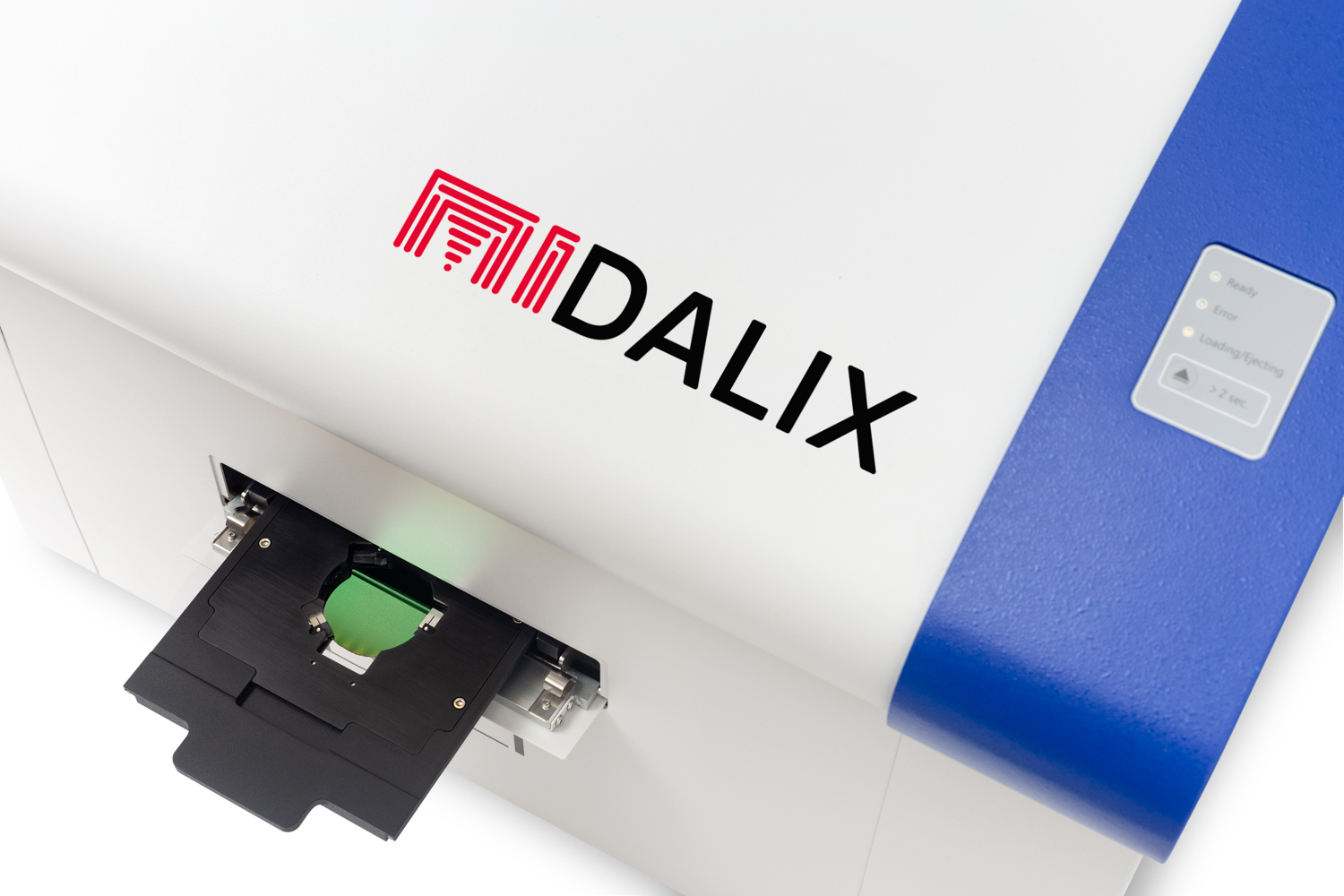

Featuring a universal design, versatile maskless operation, and micrometer-level precision, the DaLI is an ideal photolithography choice for companies in the biophysics sector.

Developed by miDALIX, the DaLI combines ease-of-use with extreme precision to bring to life the most challenging designs - and smooth software integration allows for seamless changes for all users.

So if you're in the biophysics sector, this system might be exactly what you need.

Go to https://midalix.com to learn more!

miDALIX brings an efficient maskless solution for research institutes, laboratories, universities, and other organizations.

The company’s tabletop maskless lithography system - DaLI - is designed for all standard photoresists and makes the process accessible even for users without previous experience. Since it doesn’t require a mask, the DaLI removes the challenge of sample-to-mask alignment - which saves you time and money, and makes design changes easier than ever.

Ideal for cutting-edge applications in biophysics, the DaLI offers ultra-precise direct-write lithography on samples in the micrometer range. The integrated software ensures smooth operation from setup and calibration to direct conversion of CAD drawings, and acousto-optic deflectors combine with stabilized laser technology for increased precision.

“Maskless photolithography is implemented by a near-UV laser source paired with acousto-optic deflectors (AOD) for quick and precise laser beam guiding, rapidly illuminating structures with nanometer precision on the material,” explains the company. “The high light intensity achieved by using a laser source enables fast movement between regions of the sample according to structure design and optimized by software algorithms.”

For more details on the DaLI lithography process, visit https://midalix.com/technology

The versatile design and high precision make the DaLI a suitable choice if your institution works on biophysical designs and experiments.

“Photoresist materials can either directly serve as a base layer for biophysical experiments, with surfaces modified through lithographic steps, or can be used to emboss the textured surface to other biocompatible materials,” miDALIX explains.

“Photoresist surface texturing is achieved with precise control of illumination parameters, resulting in various textures exhibiting different physical properties to control flows, biocompatibility, or friction,” they added.

About miDALIX

Founded in 2017 by Anže Jerič, Dušan Babić, and Igor Poberaj, miDALIX has grown into a leading provider of maskless lithography solutions for clients in fields ranging from materials science to quantum optics, microfluidics, microelectronics, and many others.

Find out why the DaLI is the system of choice for many leading companies at the forefront of innovations - go to https://midalix.com/applications to get started!